In battery testing equipment, the core of "bidirectional energy-saving technology" is like installing an "intelligent energy manager" on the device, which can save electricity and "recycle" wasted energy. Let's talk about its application principle in plain language:

What is' two-way '? ——Energy saving during both charging and discharging

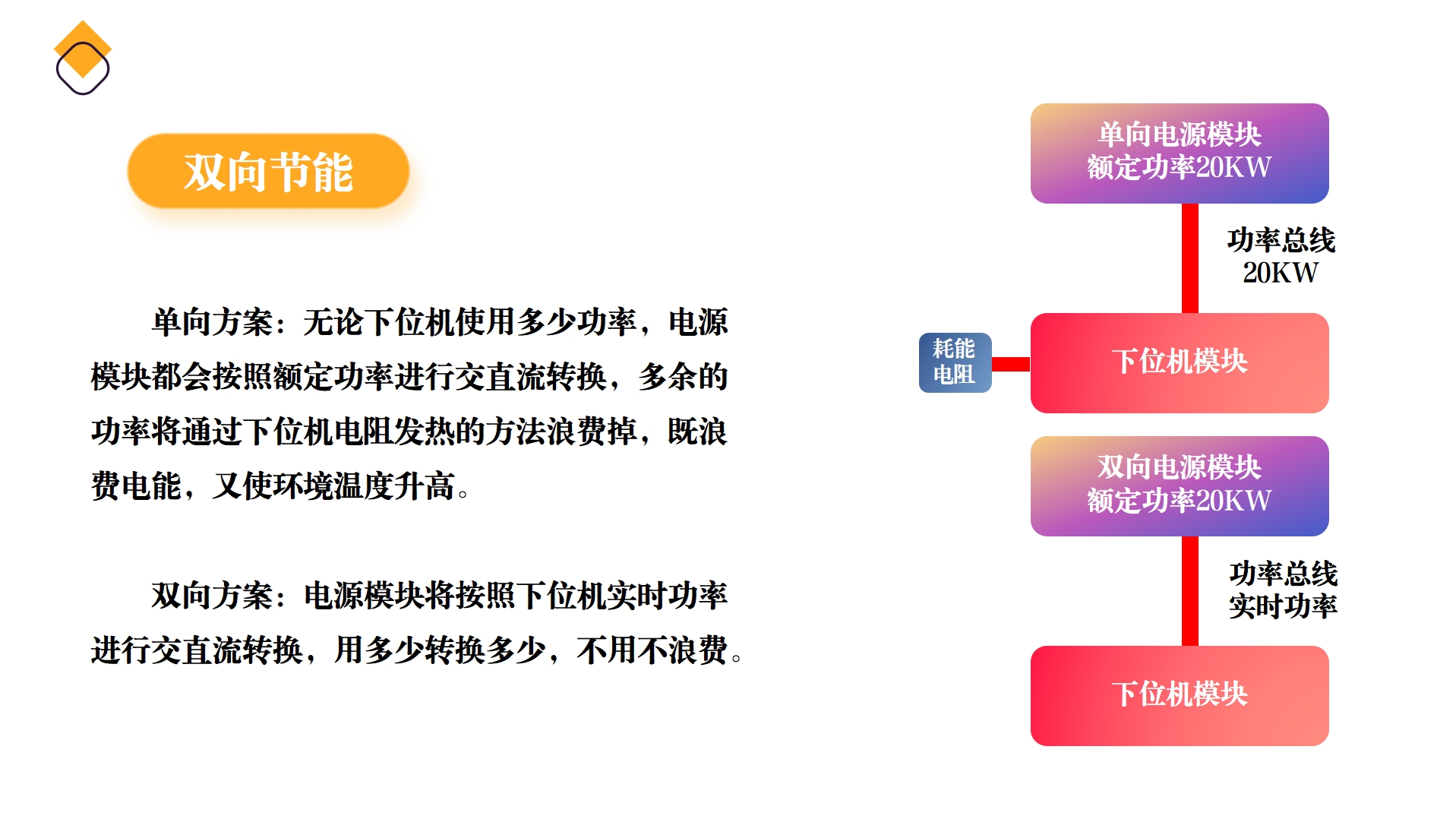

Pain points of traditional battery testing:

When testing batteries, the device needs to simulate the charging and discharging process of the battery. For example, when discharging a battery, traditional methods may directly convert electrical energy into thermal energy (such as using a heating wire to dissipate heat), which is like pouring out unfinished water directly, wasting all energy.

Two way meaning:

Bidirectional energy-saving technology enables devices to efficiently absorb electrical energy during charging, and not waste it during discharging, but instead "recycle and reuse" it, just like using a bucket to collect water, the leftover water can be reused next time.

How to achieve "energy conservation"? ——The key lies in the 'bidirectional flow of energy'

Step 1: "Recovering Energy" during Discharge

When the battery is discharged, the device no longer uses heating wires to "burn" the electrical energy, but instead uses a device called a "bidirectional converter" (similar to a bidirectional switch) to convert the electrical energy released by the battery into a form suitable for use in the power grid or other equipment.

✅ For example, when a battery is discharged, the electrical energy generated would originally be converted into heat and dissipated. Now, through an inverter, this electrical energy is "fed" to the grid (such as charging the grid), or directly used by other charging batteries, which is equivalent to recycling the "wasted electricity".

Step 2: Efficient utilization during charging

When the device charges the battery, bidirectional energy-saving technology optimizes the power input for charging and reduces energy loss during the charging process (such as reducing heat generation, electromagnetic losses, etc.).

✅ For example, traditional charging may require 10 kWh of electricity, but efficient circuit design and control algorithms allow it to complete the same amount of charging with only 8 kWh, saving the remaining 2 kWh

3. Popular metaphor: Bi directional energy-saving is like a "household water circulation system"

Traditional detection: Water from the faucet → Pour out the vegetables directly after washing (wasting energy from electricity to heat)

Bidirectional energy-saving:

① Catch the vegetable washing water in a bucket → filter and flush the toilet (recover the discharged energy to other devices);

② Install a water-saving valve on the faucet → reduce water discharge but wash equally clean (efficient and energy-saving during charging).

4. Actual effect: Energy saving, environmental protection, and cost saving